Ultrasonic Wire Welding Produces More Reliable Wire Harnesses

Wire harnesses must perform reliably in increasingly demanding environments, from automotive and aerospace systems to industrial electronics and renewable energy applications. As expectations for electrical performance and long-term durability rise, manufacturers are turning to technologies that improve consistency, conductivity and reliability. One solution stands out for its proven effectiveness: ultrasonic wire welding.

Ultrasonic welding, long valued for its speed and repeatability, continues to gain traction as wire harness manufacturers look for ways to reduce electrical resistance, eliminate weak points and ensure stable performance under harsh operating conditions. Sonobond Ultrasonics is a leader in this technology with robust, reliable ultrasonic welding systems designed specifically for wire bundling, termination and conductor joining.

Why Ultrasonic Welding Matters for Wire Harness Reliability

Wire harnesses are only as strong and reliable as the connections that hold them together. Traditional crimping and soldering methods have served the industry for decades, but they have many drawbacks. These disadvantages include inconsistency in operator technique, inconsistent material flow, hot zones, arcs, sparks, fumes and potential long-term reliability concerns.

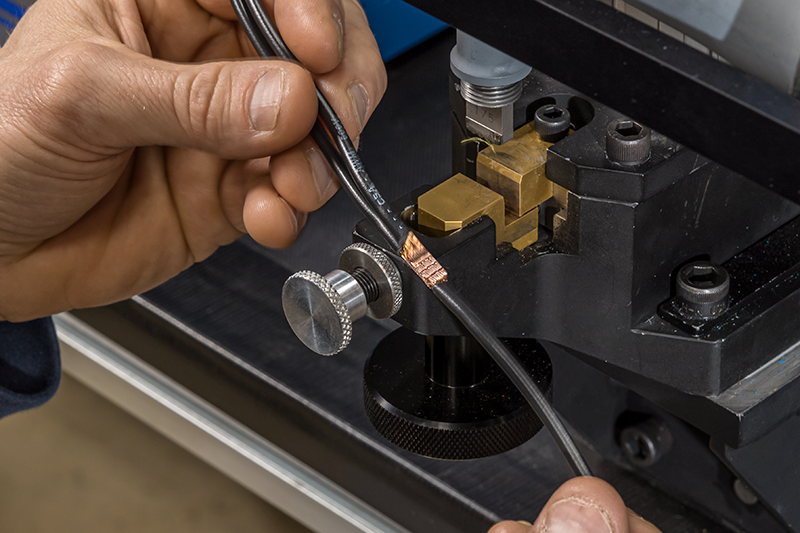

Ultrasonic wire welding solves these issues through a solid-state process that uses high-frequency vibrations and pressure, rather than heat or filler materials, to create a clean, uniform metallurgical bond.

Some of the most critical advantages for wire harness manufacturers include:

1. Consistency Across Every Weld

Because ultrasonic wire welding doesn’t depend on manual technique, it reduces variability from weld to weld. Operators can precisely control weld parameters, ensuring every connection meets the same quality requirements. This is especially important for large harnesses with multiple identical junctions.

2. Reduced Electrical Resistance

A high-performance wire harness must maintain low resistance to ensure optimal current flow. Ultrasonic welding compresses the wire strands, breaks up surface oxides and bonds the metal without melting it. The result is a dense, uniform connection with minimal electrical loss.

3. Enhanced Strength and Longevity

Because ultrasonic wire welding does not introduce high heat, it avoids the microstructural changes and brittleness associated with soldering. This makes the welded joint more resilient to:

- Vibration

- Thermal cycling

- Mechanical stress

- Exposure to harsh or corrosive environments

These benefits are essential in industries such as transportation, where wire harness failures can result in costly downtime or safety issues.

4. Environmentally Friendly and Cost-Efficient

Ultrasonic wire welding produces no fumes, does not require consumables and uses very little energy. As manufacturers strive to meet sustainability goals and reduce production waste, ultrasonic wire welding offers an eco-friendly – and cost-effective – path forward.

In fact, this technical article in the Journal of Manufacturing Processes notes that new energy vehicles rely on large numbers of wiring harnesses to connect and power their electrical systems. As a clean, solid-state joining method, ultrasonic metal welding has demonstrated significant advantages for these applications. Its benefits make ultrasonic metal welding a strong fit not only for new energy vehicles, but also for demanding industries such as power electronics, aerospace and medical technology.

How Ultrasonic Welding Improves Wire Assembly Performance

Whether joining stranded wires, bundling copper conductors, or attaching terminals, ultrasonic metal welding provides measurable improvements in performance. Below are some of the most impactful contributions to wire assembly quality.

Improved Electrical Conductivity

Because ultrasonic welding creates a direct metal-to-metal bond, the resulting joint has exceptional conductivity. The elimination of solder or connectors means fewer failure points and improved efficiency in high-demand electrical systems.

Repeatable Quality in High-Volume Production

Wire harness manufacturers often operate at scale, needing thousands, or hundreds of thousands, of identical wire connections. Ultrasonic welding supports:

- Automated material handling

- Programmable weld parameters

- Closed-loop process monitoring

This ensures repeatable quality while reducing labor and rework costs.

Compatibility with a Range of Materials

Ultrasonic welding works with common wire materials including copper and aluminum, two metals widely used in automotive wiring, electronic assemblies and industrial controls. As weight reduction efforts grow across multiple industries, the ability to ultrasonically weld aluminum conductors is increasingly valuable.

Greater Reliability in Harsh Conditions

Applications such as off-road vehicles, heavy equipment, aerospace systems, marine vessels, and military electronics demand ultra-rugged wiring solutions. In these environments, tinned wire is often specified for its superior corrosion resistance and thermal stability. Sonobond is the only ultrasonic welding manufacturer that offers welders capable of reliably bonding tinned wire and other welded joints while maintaining exceptional resistance to vibration, shock, and extreme environmental exposure—performance that mission-critical systems require.

Ultrasonic Wire Welding Technology from Sonobond Ultrasonics

For decades, Sonobond Ultrasonics has been at the forefront of ultrasonic metal welding innovation. SpliceRite™ ultrasonic wire splicers are built to form solid-state, ultra-low-resistance welds without melting the wires or creating sparks or arc damage. The result is fast, clean bonding that delivers exceptionally strong, reliable electrical connections with consistently low resistance.

Engineered for the tough demands of automotive, aerospace, electronics and industrial manufacturing, SpliceRite systems ensure every weld is uniform, durable and clean.

Thanks to Sonobond’s exclusive Wedge-Reed bonding system, which applies high vibratory force with low-amplitude motion, SpliceRite bonders can even weld tinned or oxidized wires in a single pulse without any pre-cleaning. No other ultrasonic welding technology offers this capability.

Sonobond’s engineering team also works closely with manufacturers to customize welding solutions tailored to specific harness geometries, conductor sizes and industry requirements.

Free Ultrasonic Test Weld

To help manufacturers evaluate whether ultrasonic wire welding is the right fit for their production needs, Sonobond Ultrasonics offers a free, no-obligation viability test.

You can supply your own wire materials and Sonobond’s engineers will perform weld trials to confirm:

- Weld strength

- Conductivity performance

- Consistency and repeatability

- Compatibility with your material stack-up

This service ensures that manufacturers can validate the process before investing in a welding system.

Learn More About Ultrasonic Wire Welding

If you’re exploring how ultrasonic wire welding can improve the reliability, conductivity and performance of your wire harness assemblies, Sonobond Ultrasonics is ready to help. For more information, call our experts at 800-323-1269 or contact us here.